Freeze Drying Plant Relocation & Upgrade

A relocation of a freeze-drying plant was required as part of works associated in merging with a publically listed company. As the freeze-drying plant had been running for some years without suitable engineering and/or quality administration the process and required documentation was lacking.

After meeting with management to go through the scope of works a detailed project proposal was put together with 4 phases and appropriate timelines.

Although the plant was an existing plant, we treated this phase as a concept phase where we gathered information, evaluated gaps and looked at opportunities for improvement.

On site meetings were arranged with managers and staff to get an understanding of their roles and responsibilities while gathering crucial information about the process. Once this was complete, a high level project task list was created for review by the working group. Below is a list of the major tasks.

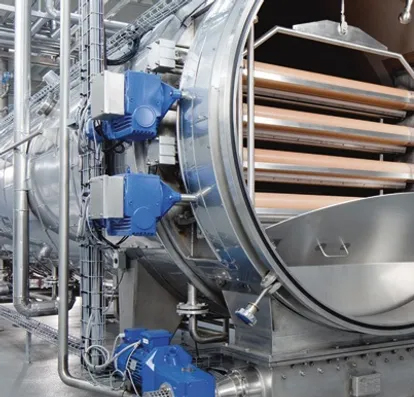

Fig. 1 - Representative image of freeze drying equipment.

Tasks requiring completion prior to Phase 2:

Phase 2 (Design)

Phase 2 is where all the requirements listed in phase 1 are completed with appropriate changes to existing designs and other associated documents.

Phase 3 (Installation): Installation of relocated plant.

Phase 4 (Commissioning): Commissioning and handover of plant to client.

View Our Services

Project Management, MEP Contractor Support, Project Management Consultancy, Manufacturing Consulting, Design Consultancy, Procurement Consultants, Process Improvement Consultants, Mechanical Engineering Consultants, Commissioning Plan, Project Management Consultants Sydney, Engineering Consultancy Melbourne

Copyright © 2024 SPN Consulting Pty Ltd. All rights reserved. ABN 33 164 420 124 | Privacy Policy | Designed and Developed by Xugar | Sitemap