Trade waste remediation & infrastructure upgrade

This project involved the successful upgrade and improvement of multiple pieces of trade waste infrastructure and piping that were required at a long-standing pharmaceutical processing plant on Victoria's western coast.

Project value : $500,000

After meeting with management to go through the scope of works a detailed project proposal was put together with multiple phases and appropriate timelines for completion, in order to remediate known areas of contamination and upgrade appropriate containment points around the site facility.

From late 2016 to early 2017 a detailed project proposal was prepared based on the client's user requirements that were put together through a thorough examination of the project's current issues and benefits wanting to be achieved through investing in the capital improvements.

On site meetings were arranged with managers and staff to get an understanding of their roles and responsibilities while gathering crucial information about the process. Once this was complete, a high level project task list was created for review by the working group. Below is a list of the major tasks.

Tasks requiring completion prior to Phase 2:

Phase 2 (Detailed Design)

Phase 2 is where all the requirements listed in phase 1 are completed with appropriate changes to existing designs and other associated documents, including the generation of a detailed scope of works - put into separate mechanical, electrical and civil requirement documents.

Once this was finalised, sign-off was completed of final design, ready for the procurement and sourcing of necessary equipment, components and installation resources.

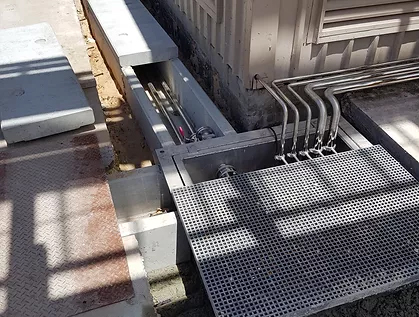

Phase 3 (Installation): Installation of new secondary containment infrastructure and piping

This phase included the management and supervision of external contractors in undertaking the fabrication of required containment tanks, as well as installation of piping, valving and instrumentation required for trade waste improvement system.

Other items included civil works of containment bunds and culverts, which acted as secondary containment structures to main tank and piping catchments.

Fig. 2 - Bund in construction

Fig. 3 - Culverts & piping

Fig. 4a - Trade wastes pits and piping during construction & installation

Fig. 4b - Completed ground well pit

Phase 4 (Commissioning): Commissioning and handover of plant to client.

The final aspect included thorough preparation of commissioning documentation and check lists - including functional specification documentation in order to confirm final programming and automation of system.

Conclusion

After all these steps were completed - a successful, operational and compliant system was handed over back to the client to continue with general operations.

View Our Services

Project Management, MEP Contractor Support, Project Management Consultancy, Manufacturing Consulting, Design Consultancy, Procurement Consultants, Process Improvement Consultants, Mechanical Engineering Consultants, Commissioning Plan, Project Management Consultants Sydney, Engineering Consultancy Melbourne

Copyright © 2024 SPN Consulting Pty Ltd. All rights reserved. ABN 33 164 420 124 | Privacy Policy | Designed and Developed by Xugar | Sitemap